So, you've decided to take on the challenge of cutting plexiglass with a table saw, huh? Well, brace yourself, my friend, because this is not a task for the faint-hearted. First things first, make sure you're wearing your superhero cape, because you're about to feel like a DIY champion. Now, before you even think about approaching that table saw, remember to put on your safety goggles. Trust me, you don't want to end up with plexiglass shrapnel in your eyes. Next, adjust the blade height to just slightly higher than the thickness of your plexiglass. Think of it as a game of limbo, but instead of avoiding a stick, you're avoiding a disastrous cut. And finally, take a deep breath, summon your inner lumberjack, and make that cut with confidence. Just remember, if all else fails, you can always blame it on a faulty table saw or an evil plexiglass conspiracy. Good luck, my fearless DIY warrior!

An interesting fact about cutting plexiglass with a table saw is that using a blade with a high tooth count, such as a triple-chip grind or a carbide-tipped blade, can help reduce chipping and splintering during the cutting process. This is because the high tooth count allows for a smoother and more precise cut, resulting in cleaner edges on the plexiglass.

When it comes to cutting plexiglass with a table saw, safety should be your number one priority. Before you even think about firing up that saw, make sure you're equipped with the proper safety gear. Put on your safety goggles to shield your precious peepers from any flying debris. Don't forget to wear gloves to protect your hands from potential cuts or splinters. And if you want to take it to the next level, consider wearing a long-sleeved shirt and pants to cover up any exposed skin. Remember, plexiglass can be a bit of a diva, so treat it with respect and caution. Take your time, go slow, and let that table saw do its magic while you stay safe and sound. Happy cutting!

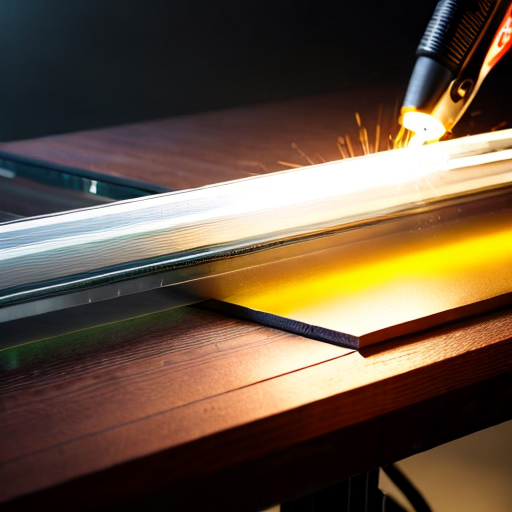

If you're ready to tackle the challenge of cutting plexiglass with a table saw, let's make sure you have everything set up for precise and accurate cuts. First things first, make sure your table saw is equipped with a fine-toothed blade specifically designed for cutting plexiglass. This will help minimize chipping and ensure clean cuts. Next, adjust the blade height to just slightly higher than the thickness of your plexiglass. This will prevent the material from getting caught or splintering as it passes through the blade. Now, it's time to set up your fence. Position it parallel to the blade, ensuring a consistent and straight cut. Double-check the measurements to make sure the fence is aligned properly. Ah, the moment of truth! Before you start cutting, take a deep breath and remind yourself to go slow and steady. Plexiglass can be a bit temperamental, so it's important to let the saw do the work. Push the plexiglass gently against the fence, maintaining a firm grip to guide it through the blade. And remember, patience is key. Rushing the process can lead to mistakes and uneven cuts. Once you've made the cut, inspect it closely. If there are any rough edges or imperfections, you can use sandpaper or a file to smooth them out. And there you have it, a step-by-step guide to setting up your table saw for precise plexiglass cuts. Now, go forth and conquer those plexiglass projects with confidence!

Fun fact: Did you know that cutting plexiglass with a table saw can be made easier by using a blade with a high tooth count? The higher the tooth count, the smoother the cut will be, reducing the chances of chipping or cracking the plexiglass. So, if you ever find yourself needing to cut plexiglass, remember to choose a blade with more teeth for a cleaner and more precise cut!

To achieve clean and accurate cuts on plexiglass with a table saw, there are a few expert tips and techniques to keep in mind. Firstly, consider using a zero-clearance insert on your table saw to minimize the risk of chipping or splintering. This will provide additional support and stability for the plexiglass as it passes through the blade. Secondly, try using a slower feed rate to prevent the plexiglass from melting or binding against the blade. This will help maintain the integrity of the material and result in smoother cuts. Additionally, using a sacrificial backing board can help reduce tear-out and provide additional support during the cutting process. Lastly, consider using masking tape along the cut line to further minimize chipping and provide a visual guide for precise cuts. By implementing these expert tips and techniques, you'll be well on your way to achieving clean and accurate cuts on plexiglass with your trusty table saw. Happy cutting!